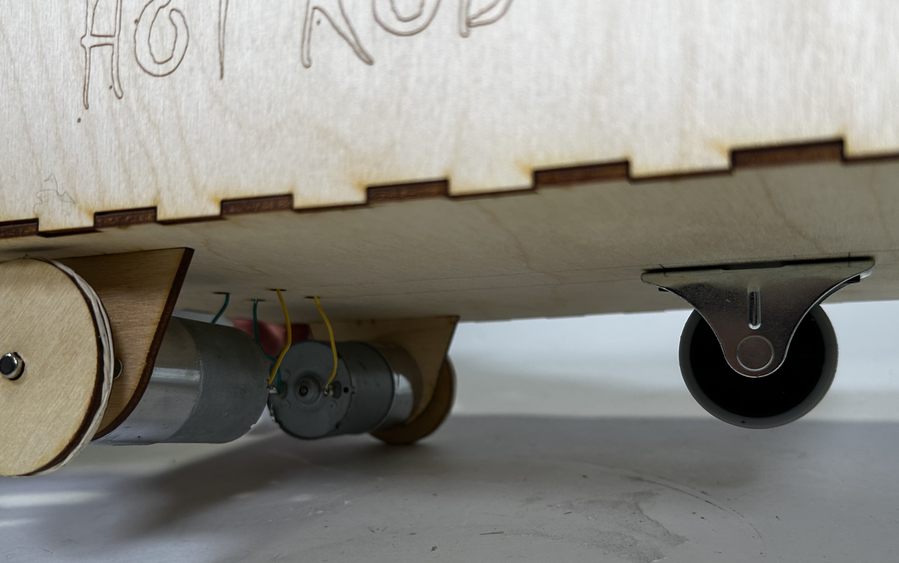

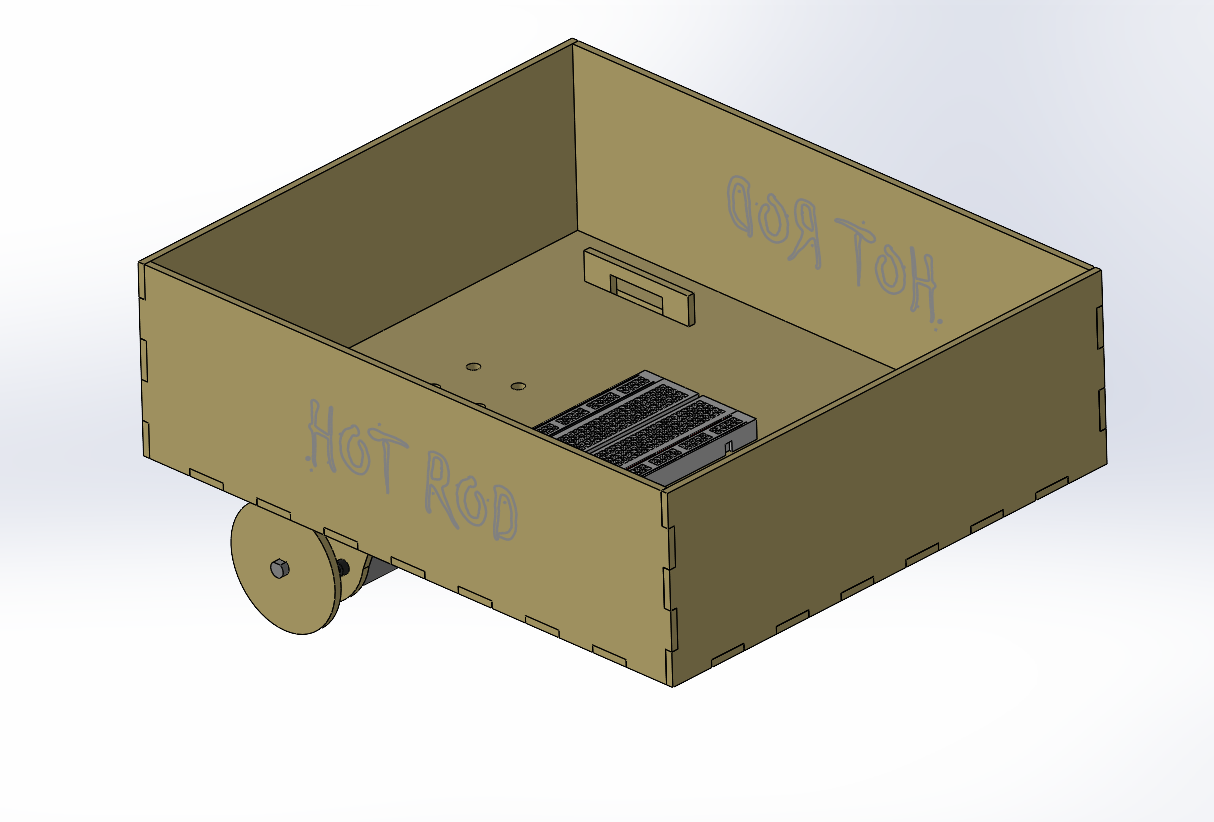

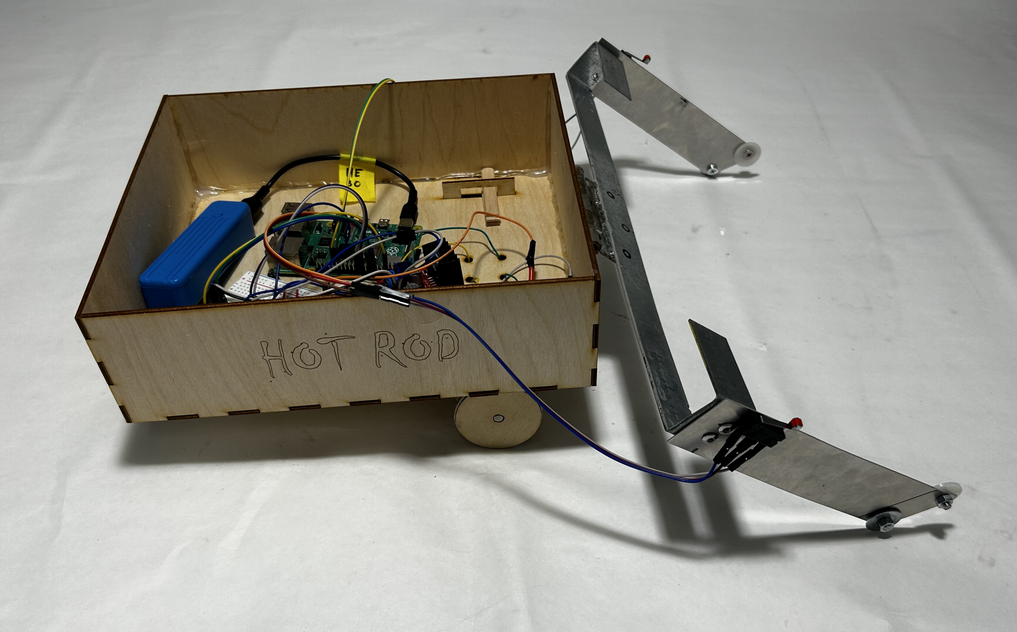

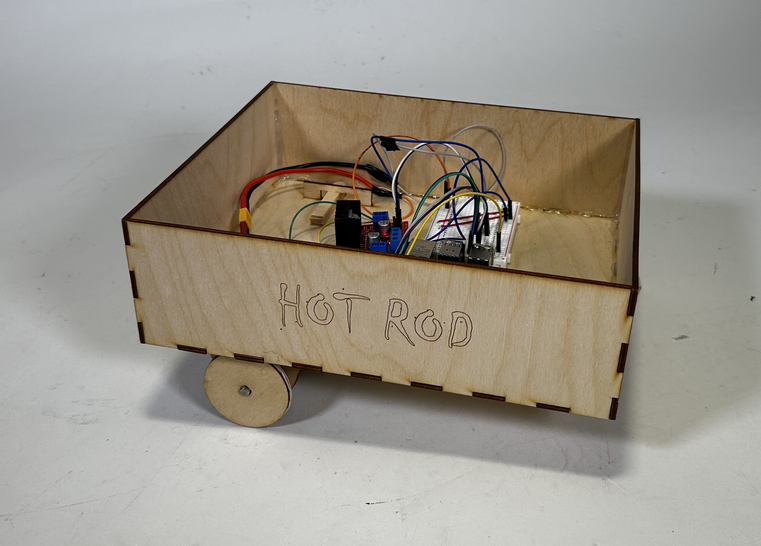

"Hot Rod" comes from two projects. The two separate projects have similar end goals with different means of achieving them. The requirements for the first project are listed below:

- The robot must be able to ascend a ramp

- The robot must not fall off the ramp

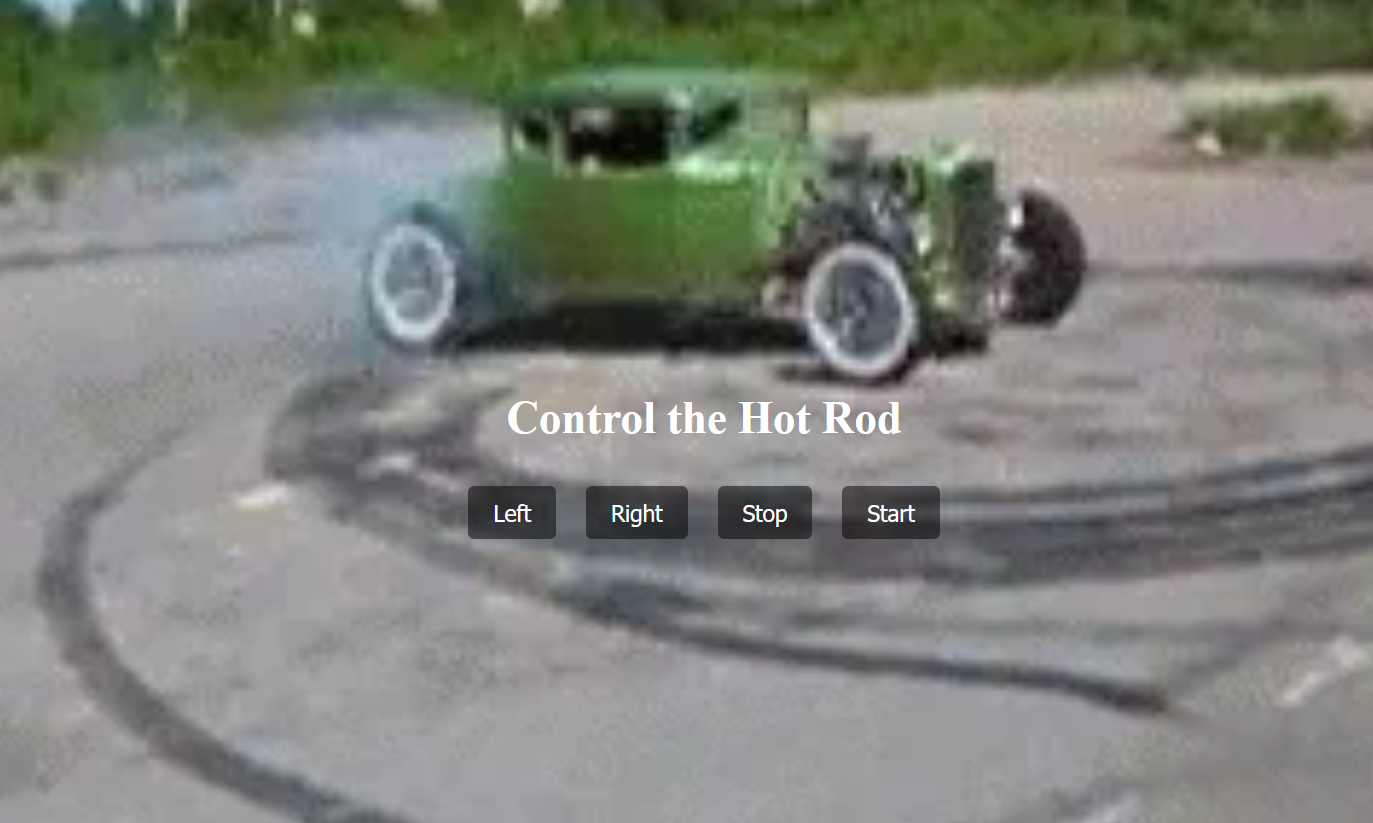

- The robot must be controlled wirelessly through the internet

- The robot cannot be touched during its ascent